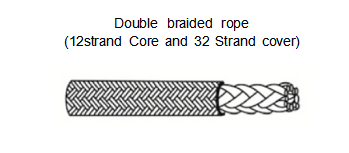

- Construction: Structure: External protective jacket + 12-strand UHMWPE braid + 3-strand nylon core

- Jacket Option 1 (Floating): Braided UHMWPE | Specific Gravity: <1.0

- Jacket Option 2 (Sinking): Braided Polyester | Specific Gravity: >1.0

- Melting Point: 147°C (UHMWPE) / 260°C (Polyester)

- Excellent UV and chemical resistance

- Excellent abrasion

POLYNEXUHMWPE -D RRR ( Reduced -Recoil -Risk)

Description

The POLYNEXUHMWPE-D RRR (Reduced-Recoil-Risk) rope represents an enhanced safety solution through its triple-layer construction. Building upon the standard POLYNEXUHMWPE RRR design, this version incorporates an additional protective outer jacket over the core safety structure. The system consists of an external UHMWPE or polyester jacket, a middle layer of 12-strand UHMWPE braid, and an inner 3-strand nylon core, creating comprehensive protection and safety mechanisms.

This advanced triple-layer rope system provides maximum durability and safety for critical maritime operations where both external protection and internal failure management are essential.

Key Advantages :

Enhanced Protection: Additional outer jacket provides superior abrasion, UV, and chemical resistance

Controlled Failure Mode: Nylon core enables progressive energy dissipation (30%+ elongation at break)

Dual Safety Mechanism: Outer jacket protects against external damage while inner core manages failure risks

Operational Reliability: Non-rotating under load, maintains tensile strength when wet

Handling Efficiency: Significantly lighter than equivalent steel wire rope

Specifications

|

Applications: Mooring operation, towing operation, Marine engineering, etc |

|||||||||

|

Size |

Weight UHMWPE JACKET |

Weight POLYESTER JACKET |

ISO MBF |

MEG4 LDBF |

|||||

|

Dia(mm) |

Cir(inch) |

g/m |

Kg/220m |

g/m |

Kg/220m |

kN |

ton |

kN |

ton |

|

20 |

21/2 |

263 |

58.0 |

275 |

60.5 |

293 |

29.9 |

264 |

26.9 |

|

24 |

3 |

368 |

81.0 |

392 |

86.1 |

413 |

42.2 |

372 |

38.0 |

|

28 |

312 |

492 |

108.1 |

531 |

116.9 |

561 |

57.3 |

505 |

51.5 |

|

32 |

4 |

633 |

139.3 |

694 |

152.8 |

737 |

75.2 |

663 |

67.7 |

|

36 |

41/2 |

794 |

174.6 |

881 |

193.8 |

923 |

94.2 |

831 |

84.8 |

|

40 |

5 |

962 |

211.6 |

1080 |

237.6 |

1144 |

116.8 |

1030 |

105.1 |

|

44 |

51/2 |

1212 |

266.6 |

1352 |

297.4 |

1378 |

140.6 |

1240 |

126.5 |

|

48 |

6 |

1422 |

312.8 |

1624 |

357.4 |

1611 |

164.4 |

1450 |

148.0 |

|

52 |

61/2 |

1662 |

365.6 |

1916 |

421.6 |

1922 |

196.1 |

1730 |

176.5 |

|

56 |

7 |

1912 |

420.6 |

2243 |

493.5 |

2189 |

223.4 |

1970 |

201.0 |

|

60 |

71/2 |

2182 |

480.0 |

2608 |

573.8 |

2522 |

257.4 |

2270 |

231.6 |

|

64 |

8 |

2489 |

547.6 |

2923 |

643.1 |

2878 |

293.7 |

2590 |

264.3 |

|

68 |

81/2 |

2809 |

618.0 |

3295 |

724.9 |

3256 |

332.2 |

2930 |

299.0 |

|

72 |

9 |

3159 |

695.0 |

3710 |

816.2 |

3633 |

370.7 |

3270 |

333.7 |

|

76 |

91/2 |

3489 |

767.6 |

4174 |

918.3 |

4022 |

410.4 |

3620 |

369.4 |

|

80 |

10 |

3839 |

844.6 |

4630 |

1018.6 |

4511 |

460.3 |

4060 |

414.3 |

|

84 |

1012 |

4246 |

934.1 |

5128 |

1128.1 |

4933 |

503.4 |

4440 |

453.1 |

|

88 |

11 |

4621 |

1016.6 |

5616 |

1235.5 |

5356 |

546.5 |

4820 |

491.8 |

|

92 |

111/2 |

5021 |

1104.6 |

6141 |

1351.1 |

5817 |

593.5 |

5235 |

534.2 |

|

96 |

12 |

5421 |

1192.6 |

6678 |

1469.2 |

6278 |

640.6 |

5650 |

576.5 |

|

100 |

121/2 |

5932 |

1305.0 |

7317 |

1609.7 |

6997 |

713.9 |

6297 |

642.6 |

|

104 |

13 |

6400 |

1408.0 |

7928 |

1744.2 |

7446 |

759.8 |

6701 |

683.8 |

|

112 |

14 |

7428 |

1634.1 |

9267 |

2038.7 |

8612 |

878.7 |

7750 |

790.9 |

***Other sizes are available upon request.

Contact Us

English

English