- Material: UHMWPE

- Specific Gravity: 0.97

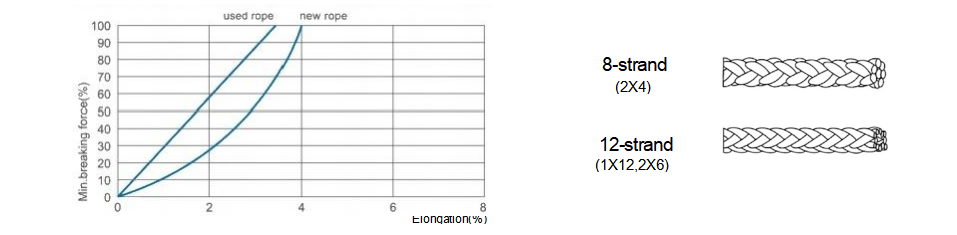

- Breaking Elongation: 4%

- Melting Point: 150°C

- Key Properties:

- Excellent Abrasion Resistance

- Excellent UV and Chemical Resistance

- Positive Buoyancy (Floats on Water)

- Tensile Strength Unaffected by Water

POLYNEXUHMWPE

Description

The POLYNEXUHMWPE Rope is an 8 or 12-strand, braided rope engineered for superior performance in demanding mooring operations. Manufactured with advanced technology, it is renowned for its exceptional stability and consistent quality.

This rope combines a set of outstanding properties that make it an ideal choice:

- Exceptional Strength-to-Weight Ratio with a Specific Gravity of 0.97, ensuring positive buoyancy.

- Superior Abrasion and Wear Resistance, outperforming many other synthetic ropes.

- Extremely Low Elongation (approx. 4% at break) for minimal stretch and superior load control.

- Excellent Resistance to UV Rays, Chemicals, and Bending Fatigue.

- Consistent Performance with tensile strength unaffected by water.

Specifications

|

Applications: Mooring line, Tug line, Super-sized commercial vessel, Wire rope replacement |

|||||||

|

Size |

Linear density |

Weight |

Breaking strength |

||||

|

|

|

|

BS(Yarns T/S-41g/d) |

BS(Yarns T/S-32g/d) |

|||

|

Cir(inch) |

Dia(mm) |

ktex |

220m(kg) |

ton |

kN |

ton |

kN |

|

1/2 |

4 |

10 |

2.2 |

1.84 |

18 |

1.33 |

13 |

|

3/4 |

6 |

23 |

5.2 |

3.88 |

38 |

3.27 |

32 |

|

1 |

8 |

39 |

8.9 |

5.72 |

56 |

4.60 |

45 |

|

1-1/4 |

10 |

61 |

14 |

9.10 |

89 |

7.35 |

72 |

|

1-1/2 |

12 |

87 |

20 |

15.10 |

148 |

10.20 |

100 |

|

1-3/4 |

14 |

117 |

26 |

18.60 |

182 |

15.30 |

150 |

|

2 |

16 |

151 |

34 |

24.50 |

240 |

19.30 |

189 |

|

2-1/4 |

18 |

190 |

43 |

29.00 |

284 |

23.40 |

229 |

|

2-1/2 |

20 |

232 |

53 |

34.00 |

334 |

28.00 |

273 |

|

2-3/4 |

22 |

281 |

64 |

41.00 |

401 |

33.00 |

322 |

|

3 |

24 |

331 |

75 |

48.00 |

473 |

38.00 |

371 |

|

3-1/2 |

28 |

445 |

100 |

76.20 |

748 |

52.20 |

562 |

|

4 |

32 |

575 |

130 |

91.20 |

895 |

68.50 |

671 |

|

4-1/2 |

36 |

720 |

162 |

107.30 |

1052 |

80.40 |

789 |

|

5 |

40 |

868 |

200 |

131.00 |

1285 |

98.20 |

964 |

|

5-1/2 |

44 |

955 |

215 |

157.00 |

1540 |

118.00 |

1158 |

|

6 |

48 |

1137 |

260 |

185.00 |

1815 |

139.00 |

1364 |

|

6-1/2 |

52 |

1342 |

300 |

212.00 |

2080 |

159.00 |

1560 |

|

7 |

56 |

1547 |

350 |

246.00 |

2408 |

184.00 |

1805 |

|

7-1/2 |

60 |

1784 |

400 |

265.00 |

2599 |

199.00 |

1952 |

|

8 |

64 |

2021 |

460 |

296.00 |

2903 |

222.00 |

2178 |

|

9 |

72 |

2598 |

590 |

365.00 |

3580 |

274.00 |

2688 |

|

10 |

80 |

3195 |

720 |

444.00 |

4355 |

333.00 |

3266 |

|

11 |

88 |

4170 |

940 |

519.00 |

5090 |

390.00 |

3825 |

|

12 |

96 |

4970 |

1120 |

606.00 |

5943 |

455.00 |

4463 |

|

13 |

104 |

5816 |

1310 |

695.00 |

6810 |

520.00 |

5096 |

|

14 |

112 |

6745 |

1520 |

783.00 |

7673 |

592.00 |

5800 |

|

15 |

120 |

7743 |

1750 |

924.00 |

9060 |

687.00 |

6730 |

|

16 |

128 |

8810 |

2000 |

1018.00 |

9980 |

779.00 |

7635 |

|

17 |

136 |

9945 |

2240 |

1122.00 |

11000 |

886.00 |

8682 |

|

18 |

144 |

11150 |

2520 |

1296.00 |

12700 |

1025.00 |

10045 |

***5% tolerance according to ISO2307

Contact Us

English

English